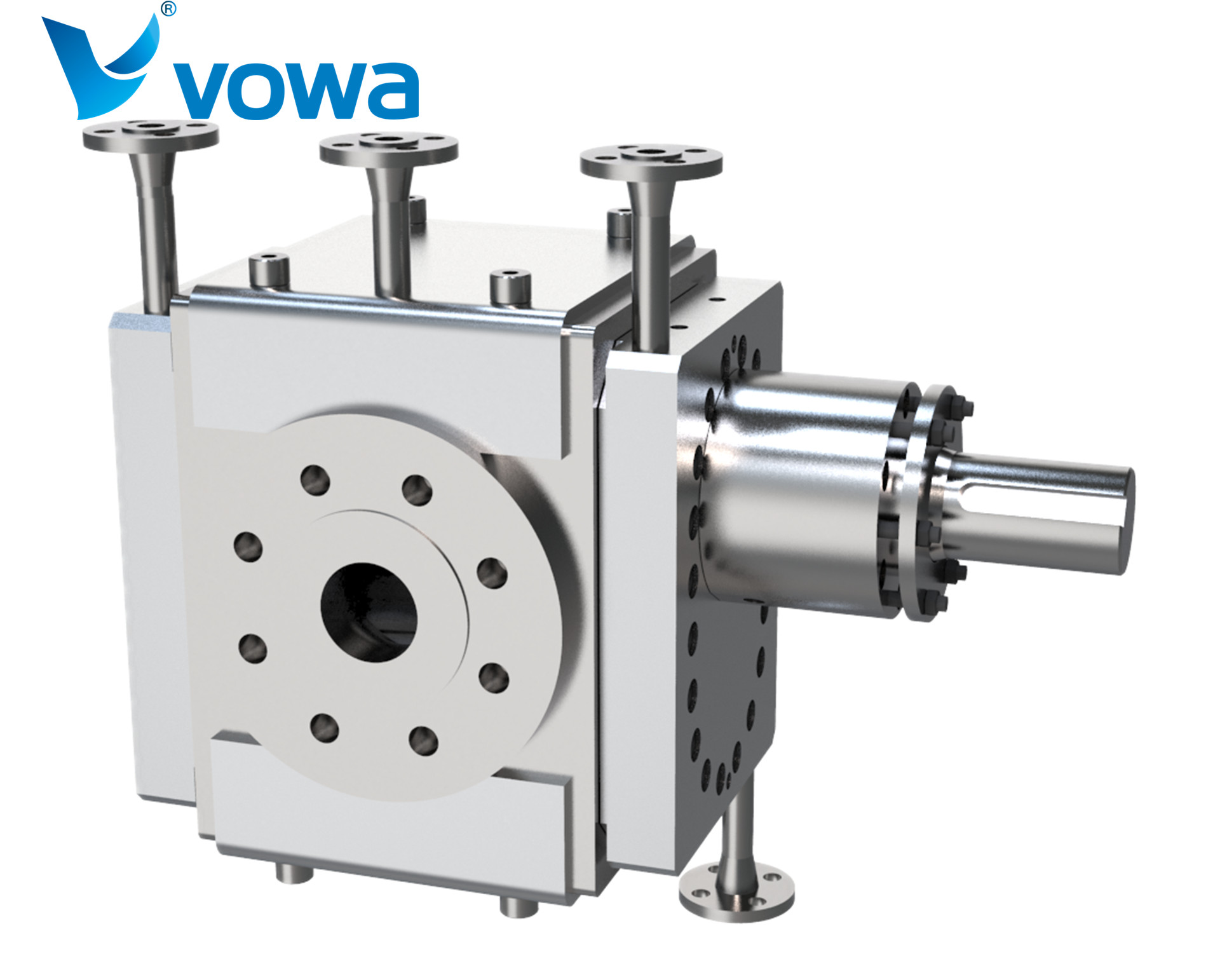

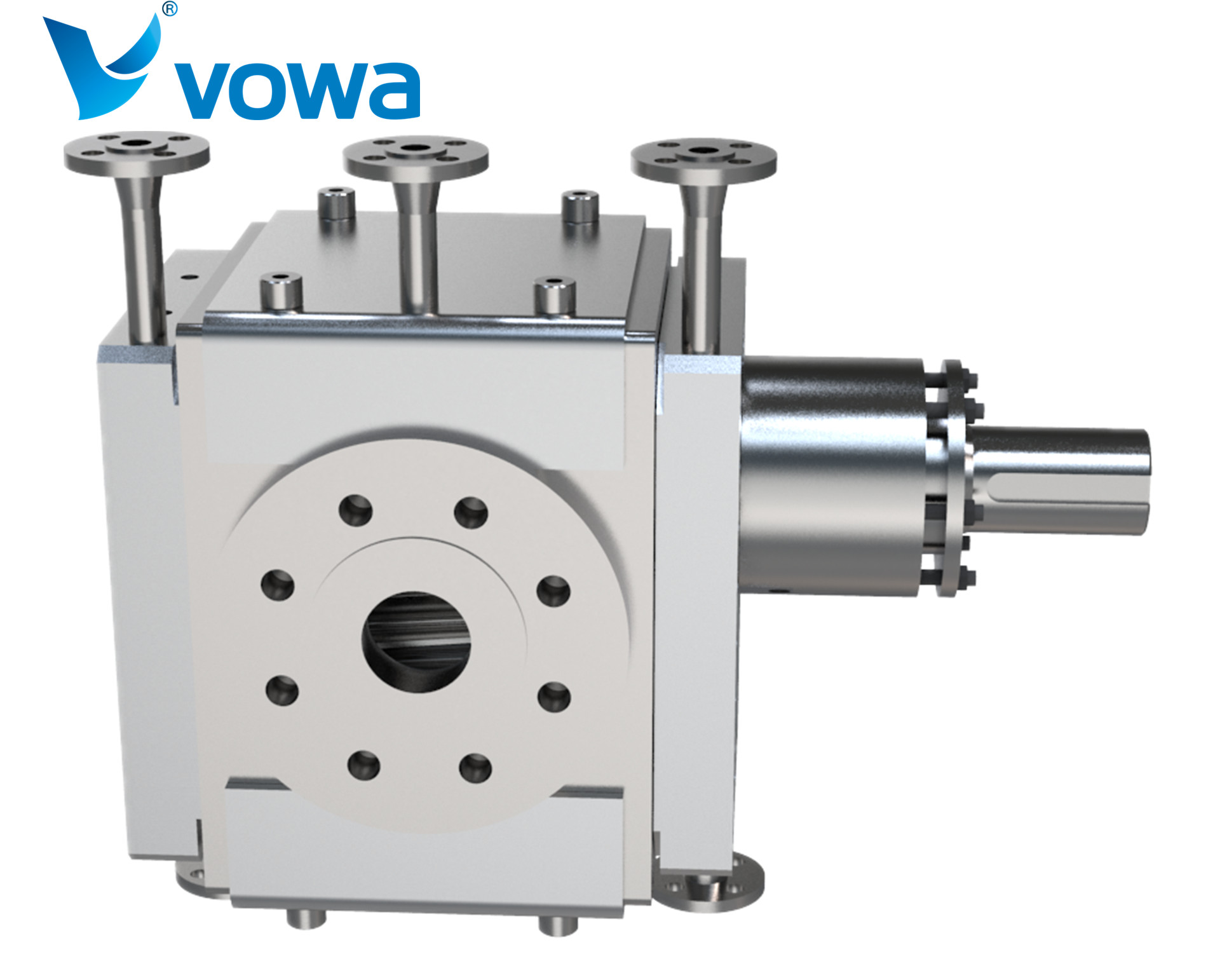

LS Series Polymer Melt Gear Pump

Booster Pump—— Low-pressure,Full Jacket

LS Series Polymer Melts Gear Pump

LS series melt gear pumps are suitable for the reaction delivery and pressurization of high-temperature and high-viscosity polymer melts with lower output pressure, such as resin, chemical fiber and other industries. They are generally installed in the melt pipeline and used as a booster pump; The body gear pump has a certain self-priming performance, and can be used to transport and pressurize polymer materials under lower vacuum suction conditions.

The main materials that can be conveyed by the melt gear pump are:

Polymer melt

PET PBT PTT

PA6 PA66 PA12

PE LDPE LLDPE HDPE HMWPE

PP EVA PB

PB PS HIPS ABS SAN

PC PEK PMMA POM

TPU PLA PBS

Other stock solutions, solutions, glues, oligomers, prepolymers, etc. in the polymer material industry;

It can also be used to transport hot melt adhesives, asphalt, paints, adhesives, pharmaceuticals, food, grease, fuels, oils, dyes, coatings, lubricants, polyols and other materials that do not contain particulate impurities.

Technical data:

Viscosity : 1E-3~30,000Pa•s (1~30,000,000cP)

Suction side pressure :(-0.00~-0.03MPa)~5MPa

Discharge side pressure : 0~5MPa

Differential pressure : 5MPa

Temperature : ≤350℃

Heating : Fully Jacketed

HT medium pressure : ≤1.6MPa

Installation method

The LS series melt gear pump is generally installed in the melt pipeline at the bottom of the reactor and used as a booster pump or a metering pump. It is driven by a motor + reducer + universal coupling. It can also be driven by a motor + reducer + flexible coupling. Shaft drive. Melt gear pump is a positive displacement forced delivery pump. The output flow of the pump can be adjusted by adjusting the speed of the pump. Frequency conversion speed regulation is recommended, which can realize the nearly linear flow output of the gear pump.

Main structure of gear pump:

Rotor type: helical or spur gear

Heating method: Heat medium heating

Sealing structure:

■ Dynamic melt seal + packing seal

■ Mechanical seal

■ Dynamic seal with cooling melt

■ High temperature resistant packing seal

Main structural materials of melt gear pump:

Pump casing: stainless steel/alloy steel/corrosion-resistant alloy

Gear: Nitrided steel/tool steel/stainless steel + coating/corrosion resistant alloy

Bearing: tool steel/copper alloy/stainless steel + coating/corrosion resistant alloy

Pump size and Technical data

|

Model |

cc/r |

Inlet |

Outlet |

Max. flow rate m3/h |

Temp |

|||

|

Low |

Medium |

High |

Ultra high |

|||||

|

<50Pa.s |

50~200Pa.s |

200~2000Pa.s |

>2000Pa.s |

|||||

|

LS-500 |

500 |

Vacuum -0.05~5.0 |

≤5.0 |

3.2 |

2.2 |

1.2 |

0.9 |

≤350℃ |

|

LS-750 |

750 |

4.9 |

3.2 |

1.8 |

1.4 |

|||

|

LS-1000 |

1000 |

5.4 |

3.8 |

2.2 |

1.9 |

|||

|

LS-1200 |

1200 |

6.5 |

4.5 |

2.6 |

2.3 |

|||

|

LS-1600 |

1600 |

8.6 |

6.0 |

3.5 |

3.0 |

|||

|

LS-2000 |

2000 |

10.8 |

7.6 |

4.3 |

3.8 |

|||

|

LS-2500 |

2500 |

10.8 |

8.1 |

4.7 |

4.1 |

|||

|

LS-3150 |

3150 |

13.6 |

10.2 |

6.0 |

5.1 |

|||

|

LS-4000 |

4000 |

13.0 |

10.8 |

7.6 |

6.5 |

|||

|

LS-6300 |

6300 |

20 |

17 |

10 |

9 |

|||

|

LS-8000 |

8000 |

22 |

17 |

13 |

12 |

|||

|

LS-9000 |

9000 |

24 |

19 |

15 |

13 |

|||

|

LS-12000 |

12000 |

32 |

26 |

18 |

16 |

|||

|

LS-18000 |

18000 |

49 |

39 |

27 |

24 |

|||

|

LS-25000 |

25000 |

68 |

54 |

38 |

34 |

|||

|

LS-38000 |

38000 |

103 |

82 |

57 |

51 |

|||

|

LS-54000 |

54000 |

146 |

117 |

82 |

73 |

|||

|

LS-80000 |

80000 |

216 |

173 |

121 |

108 |

|||

|

Please consult the manufacturer for larger or smaller specifications |

||||||||