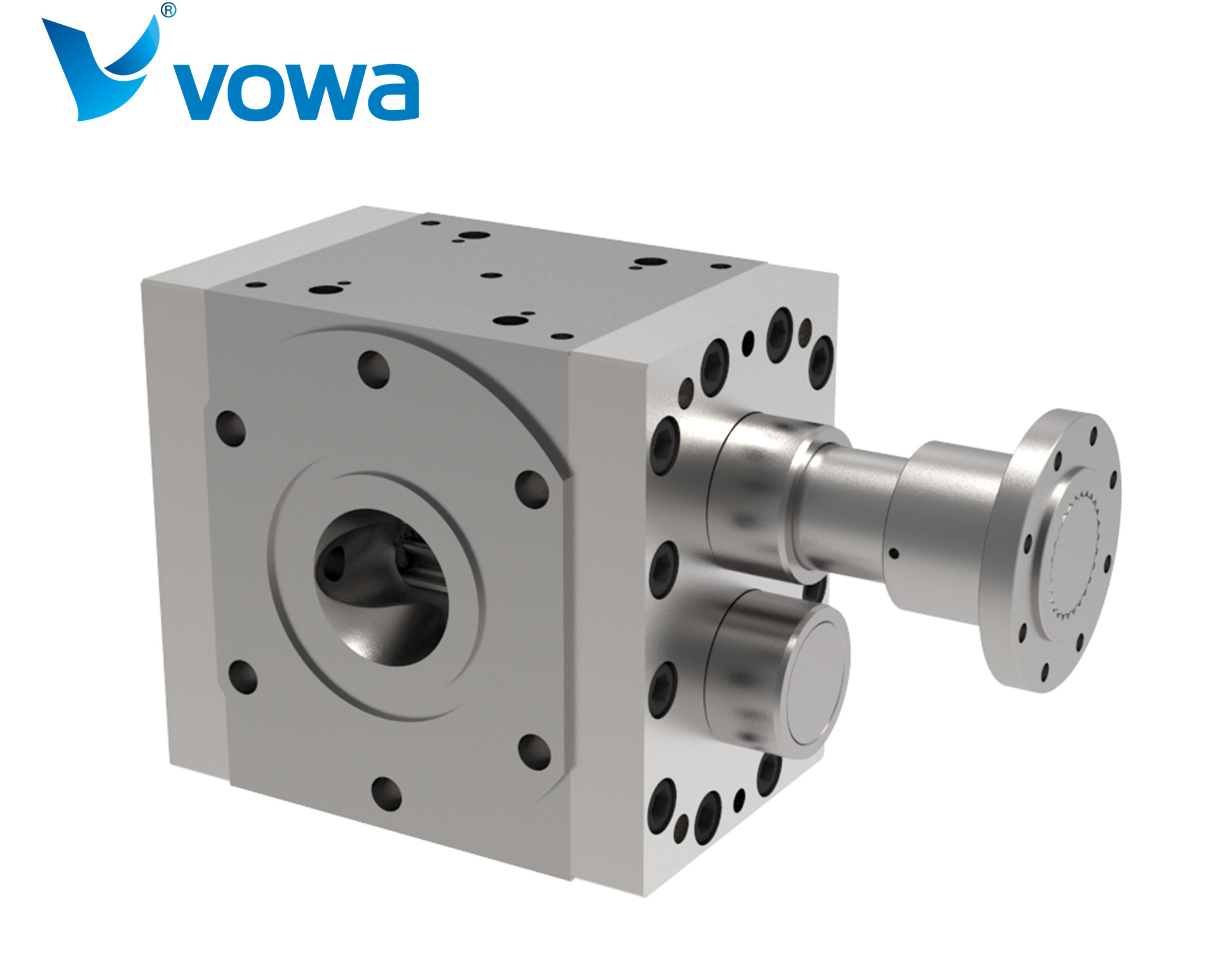

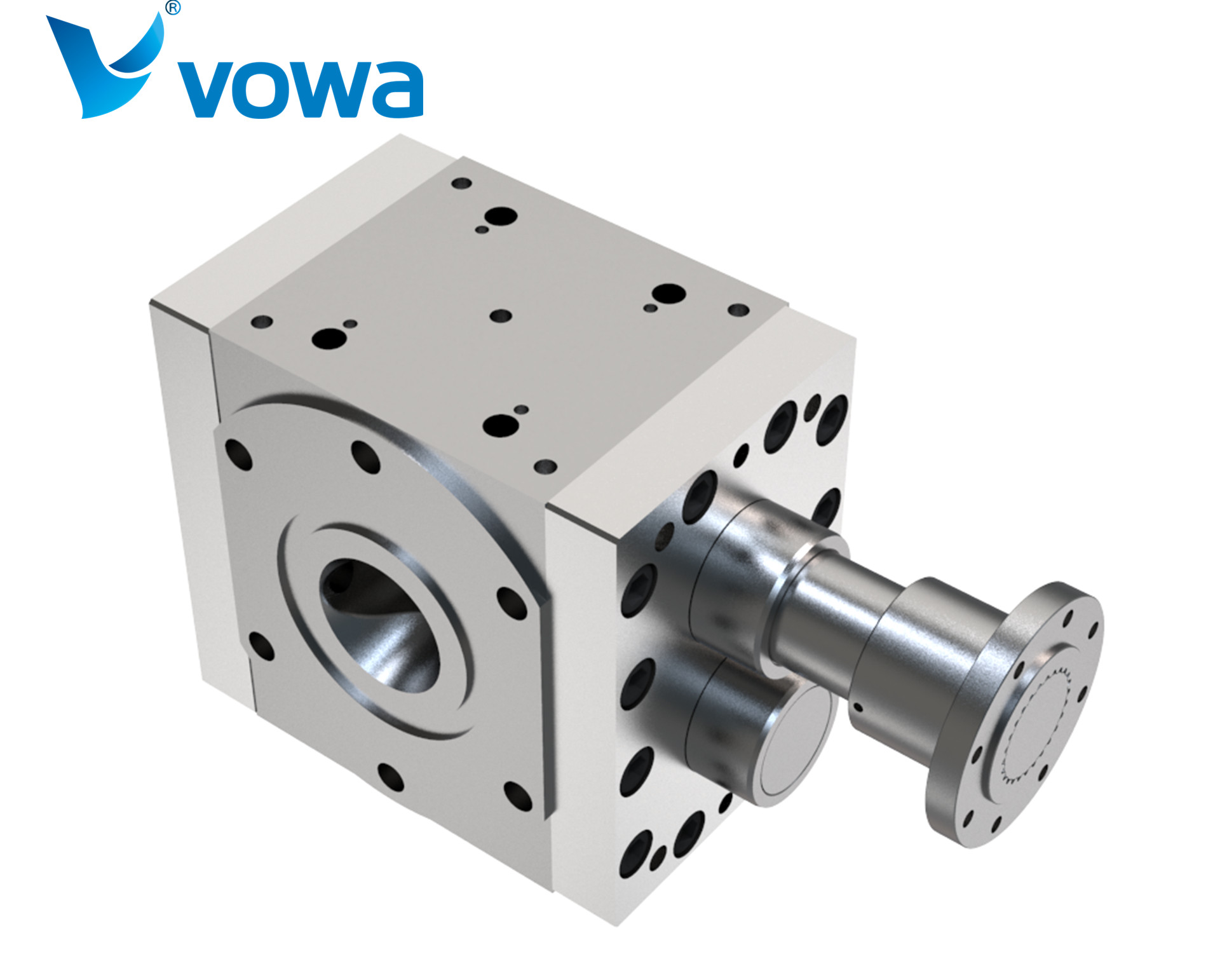

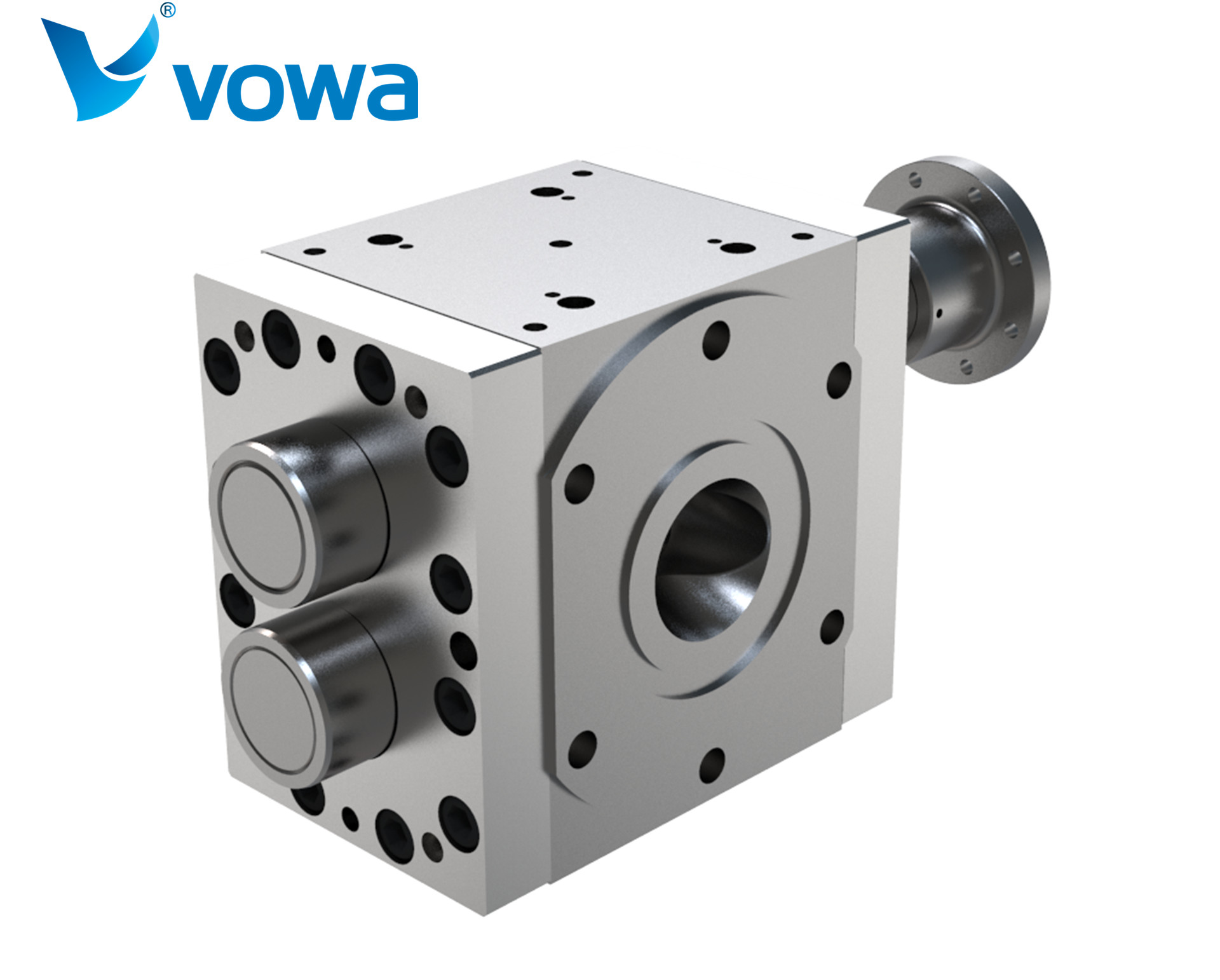

NER Series Polymer Melt Gear Pump

Gear pump for rubber and elastomer extrusion

■Optimized tooth shape design, more stable conveying, minimal fluctuation

■Runner design without dead ends, no material residue

■Special lubrication and sealing structure, suitable for rubber and easily degradable materials

■Optional wear-resistant configuration, suitable for high filling conditions

■Suitable for electric heating

We provide a full set of solutions for melt pumps, driving devices, control systems and supporting screen changers and die heads

NER series melt gear pump is a melt gear pump for the extrusion system of thermoplastic materials. It is suitable for the extrusion and transportation of thermoplastic high-viscosity polymer melt; it is generally installed between the exit of the extruder and the die and used as a melt metering pump;

The main materials that can be conveyed by the melt gear pump are:

Thermoplastic materials and their blends

PET PBT PTT

PA6 PA66 PA12

PE LDPE LLDPE HDPE HMWPE

PP EVA PB

PB PS HIPS ABS SAN

PC PEK PMMA POM

TPU PLA PBS

Rubber and elastomer materials

NR BR CR NBR

IR IIR

SBR HNBR

EPM EPDM

PU TPU

ACM CSM

ECO SI

The application of extrusion pump in rubber extrusion processing

The main function of the melt pump:

1. Significantly improve the stability of die pressure and improve product quality;

2. It can realize the nearly linear output of the flow, which is easy to control;

3. Increase the extrusion volume and increase the output;

4. Reduce the load of the extruder, save energy and reduce costs.

The main features of our company’s melt gear pump:

1. Very small pressure and flow pulsation, can achieve linear output of flow, suitable for precision extrusion system;

2. Use different structures and material configurations for different working conditions to better meet the individual needs of users;

3. It can be applied to the working conditions of high temperature (350℃), high pressure (40MPa) and high viscosity (40,000Pa•s);

4. Precise structure, high precision and long life.

The main structure of NER series melt gear pump:

Rotor type: helical or spur gear

Heating method: electric heating/heat medium heating

Sealing structure:

■ Dynamic melt seal + packing seal

■ Mechanical seal

■ Dynamic seal with cooling melt

Material configuration of the main structure of the melt gear pump

|

Material group |

case |

gear |

bush |

End plate |

Features and applicable working conditions |

Remarks |

|

|

A |

Standard |

Nitrided steel |

Nitrided steel |

Tool steel |

alloy steel |

Good wear resistance, high toughness, high cost performance Suitable for most working conditions with low abrasion |

Spare parts support |

|

H |

High wear resistance |

Nitrided steel |

High speed steel /coating |

High speed steel /ceramics |

alloy steel |

High strength, high wear resistance Suitable for abrasive wear conditions |

Need to be customized |

|

SS |

Corrosion resistant type |

stainless steel |

Nitrided steel |

Tool steel |

stainless steel |

Wear-resistant and corrosion-resistant Suitable for low corrosive conditions |

Need to be customized |

|

HS |

High corrosion resistance |

stainless steel |

Stainless tool steel |

Stainless tool steel |

stainless steel |

High corrosion resistance Suitable for highly corrosive working conditions |

Need to be customized |

|

T |

Special type |

Special alloy |

Special materials |

Special materials |

Special materials |

High temperature resistance or high corrosion resistance Suitable for working conditions with special requirements |

Need to be customized |

Main technical features of NER series melt gear pump:

1. Optimized melt flow channel design: eliminate dead corners in the flow channel, reduce polymer residues to a minimum, and improve the quality of products;

2. Improved gear parameter design: more accurate rotation displacement design makes the output pressure more stable and adapts to precise extrusion conditions;

3. A wide range of applicable viscosity: different sealing methods can be applied to working conditions from low viscosity to very high viscosity;

4. A variety of installation methods: to meet the individual needs of users;

5. High-precision manufacturing and excellent heat treatment: more precise and more durable;

Technical data:

Viscosity : 1~40000Pa•s(1~40,000,000cP)

Suction side pressure : 0~30MPa

Discharge side pressure : 0~40MPa

Differential pressure : 25MPa

Temperature : ≤350℃

Heating : Electric heating

The installation structure of melt gear pump:

It is recommended to use a universal coupling to connect the reducer and the melt pump to eliminate the effects of thermal deformation; the melt gear pump is a positive displacement forced delivery pump, and the pump output flow can be adjusted by adjusting the pump speed. It is recommended to use frequency conversion adjustment The speed mode can realize the nearly linear flow output of the gear pump.

Pump size and Technical data

|

Model |

cc/r |

Inlet |

Outlet |

Max. flow rate m3/h |

Temp |

||

|

Low |

High |

Ultra high |

|||||

|

<200Pa.s |

200~2000Pa.s |

>2000Pa.s |

|||||

|

NER -5 |

5 |

0~30 |

≤40.0 |

0.028 |

0.019 |

0.012 |

≤350℃ |

|

NER -10 |

10 |

0.054 |

0.038 |

0.024 |

|||

|

NER -20 |

20 |

0.108 |

0.076 |

0.049 |

|||

|

NER -32 |

32 |

0.173 |

0.121 |

0.078 |

|||

|

NER -50 |

50 |

0.270 |

0.189 |

0.122 |

|||

|

NER -75 |

75 |

0.365 |

0.243 |

0.162 |

|||

|

NER -100 |

100 |

0.486 |

0.324 |

0.216 |

|||

|

NER -160 |

160 |

0.778 |

0.518 |

0.346 |

|||

|

NER -200 |

200 |

0.972 |

0.648 |

0.432 |

|||

|

NER -250 |

250 |

1.080 |

0.675 |

0.473 |

|||

|

NER -355 |

355 |

1.5 |

0.9 |

0.7 |

|||

|

NER -500 |

500 |

2.2 |

1.2 |

0.9 |

|||

|

NER -750 |

750 |

3.2 |

1.8 |

1.4 |

|||

|

NER -1000 |

1000 |

3.8 |

2.2 |

1.9 |

|||

|

NER -1200 |

1200 |

4.5 |

2.6 |

2.3 |

|||

|

NER -1600 |

1600 |

6.0 |

3.5 |

3.0 |

|||

|

NER -2000 |

2000 |

7.6 |

4.3 |

3.8 |

|||

|

NER -2500 |

2500 |

8.1 |

4.7 |

4.1 |

|||

|

NER -3150 |

3150 |

10.2 |

6.0 |

5.1 |

|||

|

NER -4000 |

4000 |

10.8 |

7.6 |

6.5 |

|||

|

NER -6300 |

6300 |

17.0 |

10.2 |

9.2 |

|||

|

NER -8000 |

8000 |

17.3 |

13.0 |

11.7 |

|||

|

Please consult with the manufacturers for the bigger or lower specification |

|||||||

The flow rate of the melt gear pump is related to the working speed, material viscosity, and working pressure. Please consult the manufacturer for specific selection.

The selection needs to provide parameters: 1 flow or output 2 material name 3 material viscosity 4 material corrosivity/toxicity 5 inlet and outlet pressure (pressure difference) 6 operating temperature