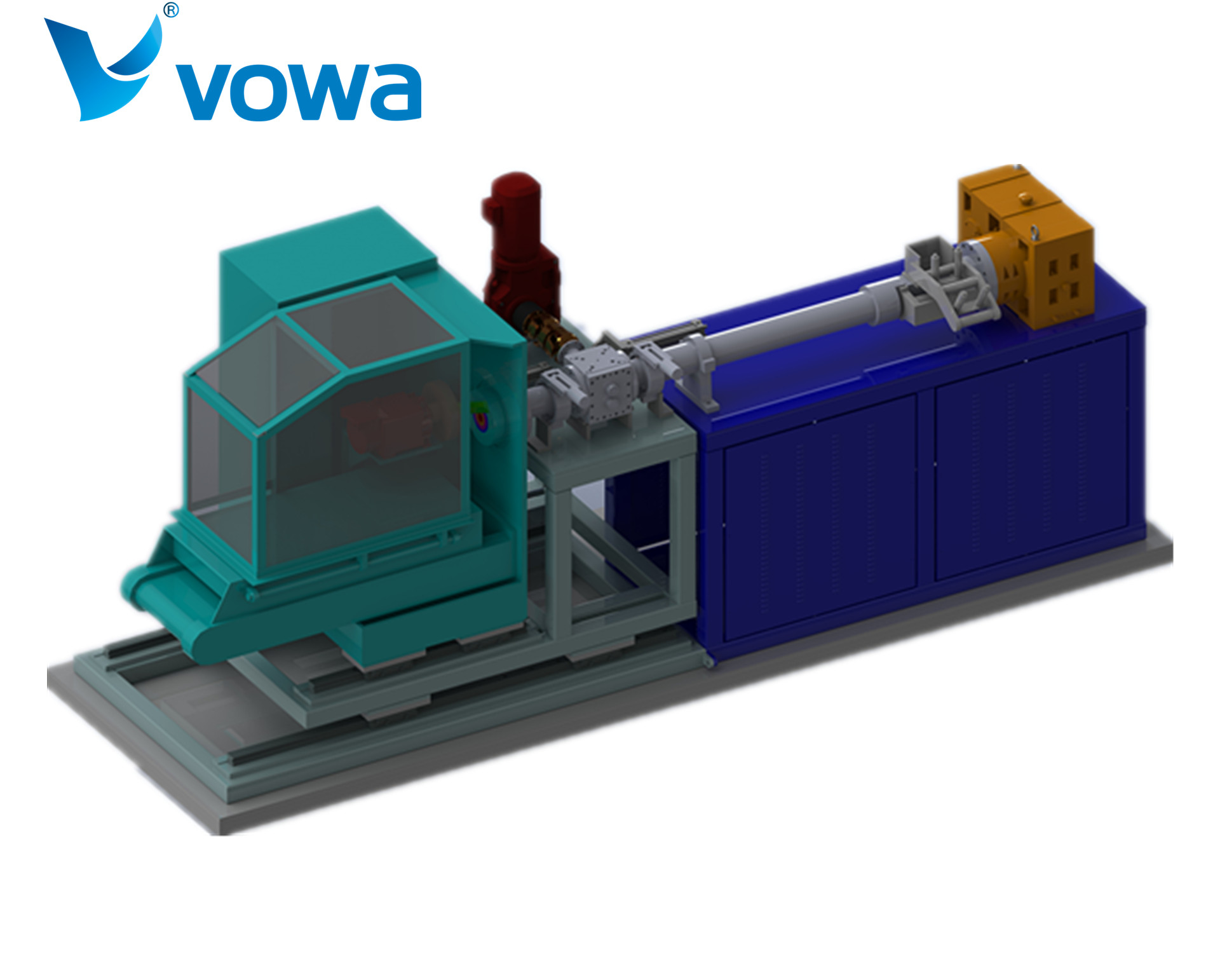

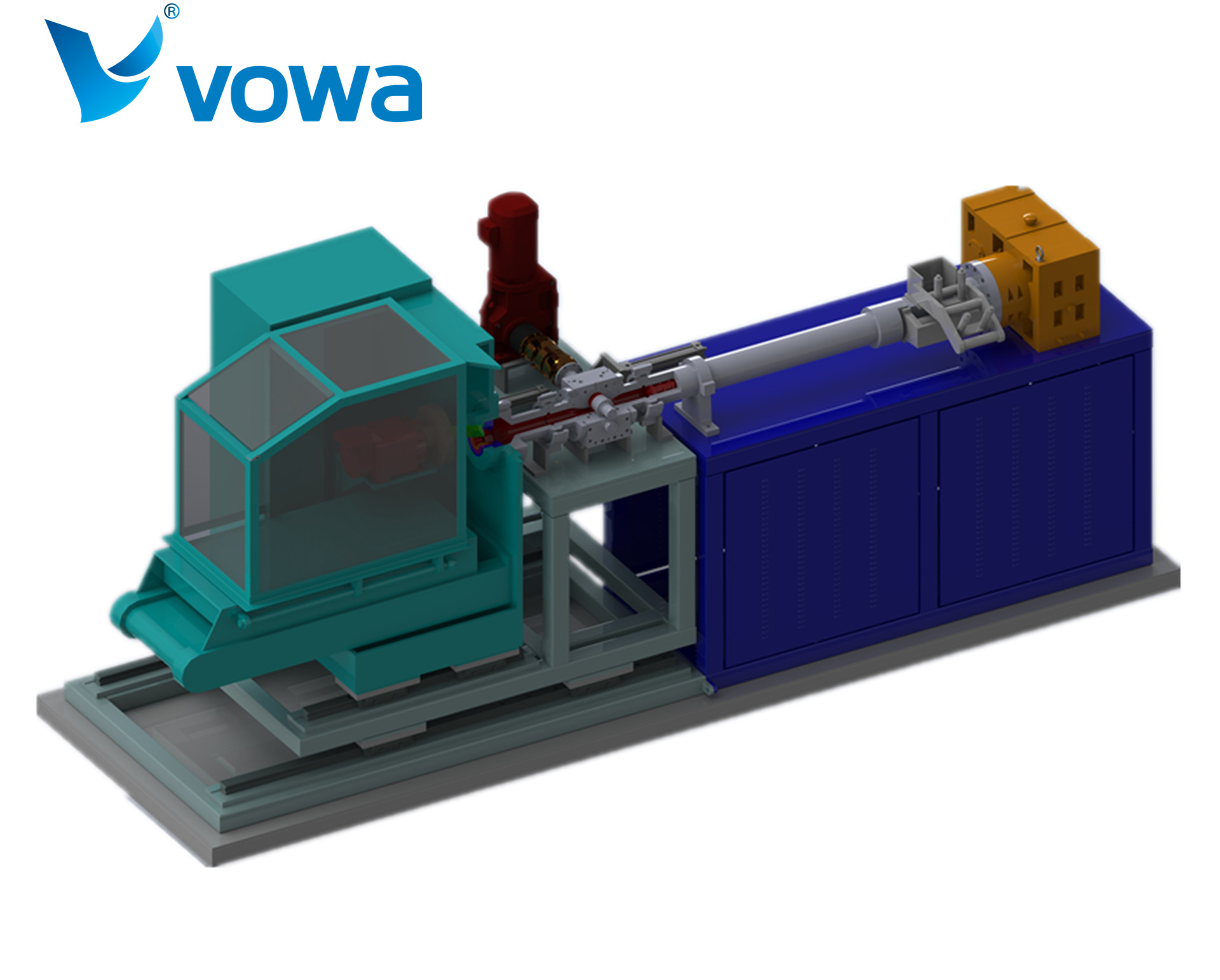

VRP Series Continuous Cold Feed Rubber Preformer

VRP Series Continuous Cold Feed Rubber Preformer

-----Realize continuous cold feeding of rubber substrate, reduce labor intensity, improve production efficiency, and reduce loss

-----Melt gear pump precision metering delivery, high and stable output of blanks

-----The servo-controlled cutter system realizes intelligent control with feedback and accurately controls the weight of the rubber blank

-----Control system with database, easy on-site operation

-----Realize remote diagnosis and remote control

Main application:

EPDM, NBR, CR, SBR,

HNBR, ACM, ……

Prefabricated molding of various rubber, elastomers and other materials, which can be applied to medium and high hardness strip, ring, three-dimensional and special-shaped complex rubber blanks;

Applicable rubber types are wide, and the extruded rubber embryo has high precision and does not contain air;

Especially suitable for the production of miscellaneous rubber parts, O-rings, oil seals, valves, golf balls, auto parts, shoe soles and other products

Rubber production process:

Plasticizing -- Mixing -- Filter Rubber -- Calendering Extrusion -- Cutting -- Weighing -- Vulcanization

Use continuous cold feed preformer to produce rubber blanks to simplify the process and improve production efficiency

Main advantag

-----Continuous cold feeding, eliminating the package and filling process, greatly reducing the labor intensity of workers;

-----Since continuous production is realized, there is no waste during the startup and shutdown phases of the plunger preformer, which reduces material loss;

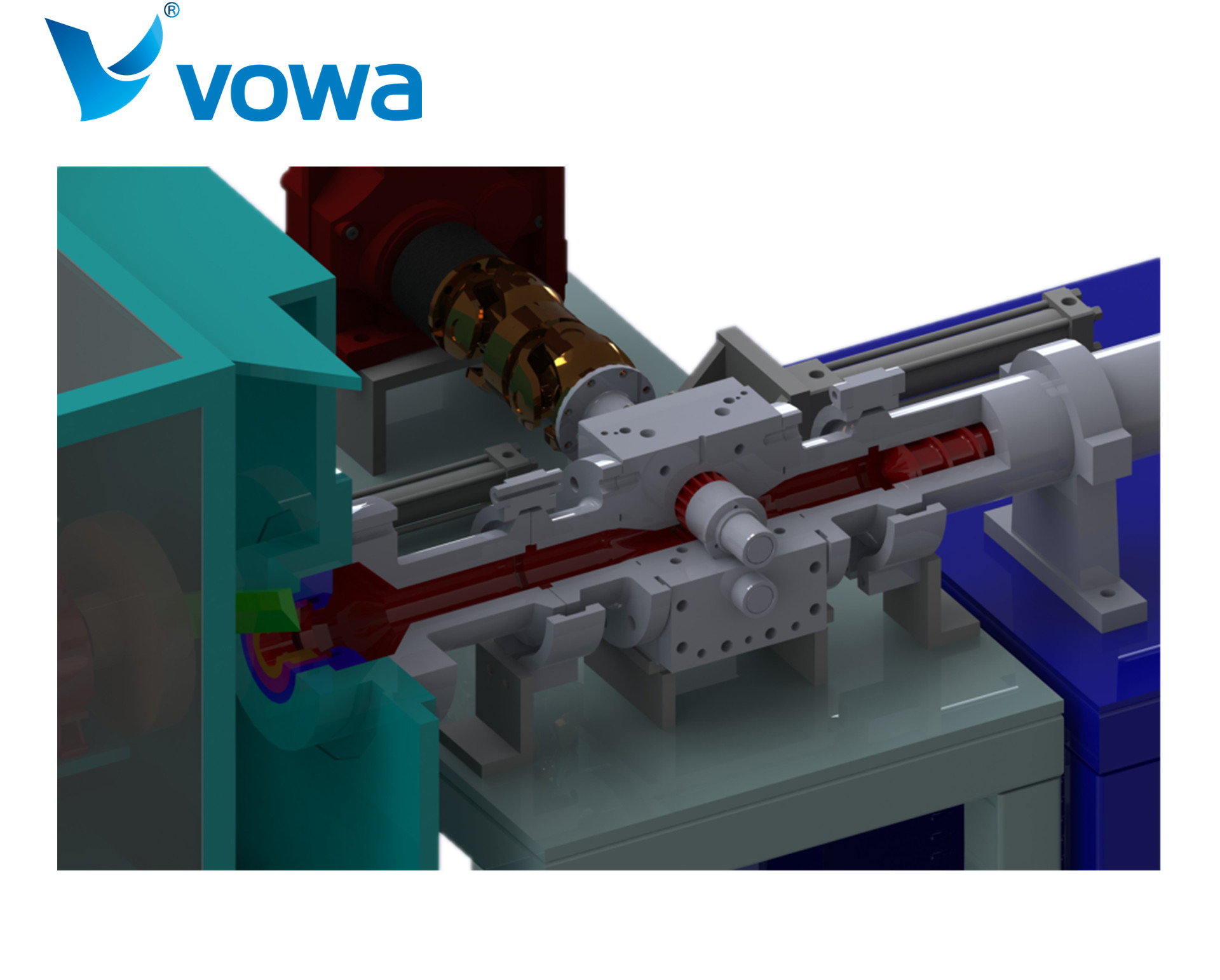

-----The melt gear pump device can realize the precise metering of the rubber material, so that the material can be transported at a constant pressure and flow rate; at the same time, the high pressure provided by the gear pump can realize the online filtering of the rubber material;

-----The servo-controlled cutter system makes the cutting precision of the rubber blank higher;

-----The high-precision weighing system accurately feeds back the weight of the rubber blank to the control system, and intelligently controls the speed matching of the screw, gear pump and cutter;

-----Remote diagnosis and remote control, maintenance is timely and simple;

Working principle

The continuous cold feeding rubber preformer consists of extruder, melt gear pump, hydraulic system, heating system, cutting system, weighing system and electric control system

The cold feed extruder transports the rubber to the gear pump, and the gear pump continuously supplies the material to the head cutter. The intelligent control system closely connects the high-speed cutter with the rubber flow of the gear pump to obtain high-precision rubber embryo. The system contains a complete set of database. The electronic scale can feedback the weight of rubber embryo and adjust the precision automatically. Through continuous feeding by gear pump, the fluctuation of pressure is reduced, and the product quality is improved. The pressure up to 350 bar enables the rubber to be filtered synchronously before preforming.

Model and technical parameters

|

Model |

unit |

|

|||||

|

Screw diameter |

mm |

70 |

90 |

120 |

180 |

250 |

320 |

|

Aspect ratio |

|

12:1 |

12:1 |

14:1 |

14:1 |

14:1 |

14:1 |

|

Maximum speed of gear pump |

rpm |

50 |

50 |

40 |

40 |

30 |

30 |

|

Heating/cooling area |

|

3 |

3 |

3 |

4 |

4 |

5 |

|

Maximum pressure |

MPa |

35 |

35 |

35 |

35 |

35 |

35 |

|

Maximum die diameter |

mm |

65 |

65 |

80 |

80 |

120 |

140 |

|

Cutting speed |

|

35~350 |

35~350 |

35~350 |

35~350 |

35~350 |

35~350 |

|

Product accuracy |

rpm |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |