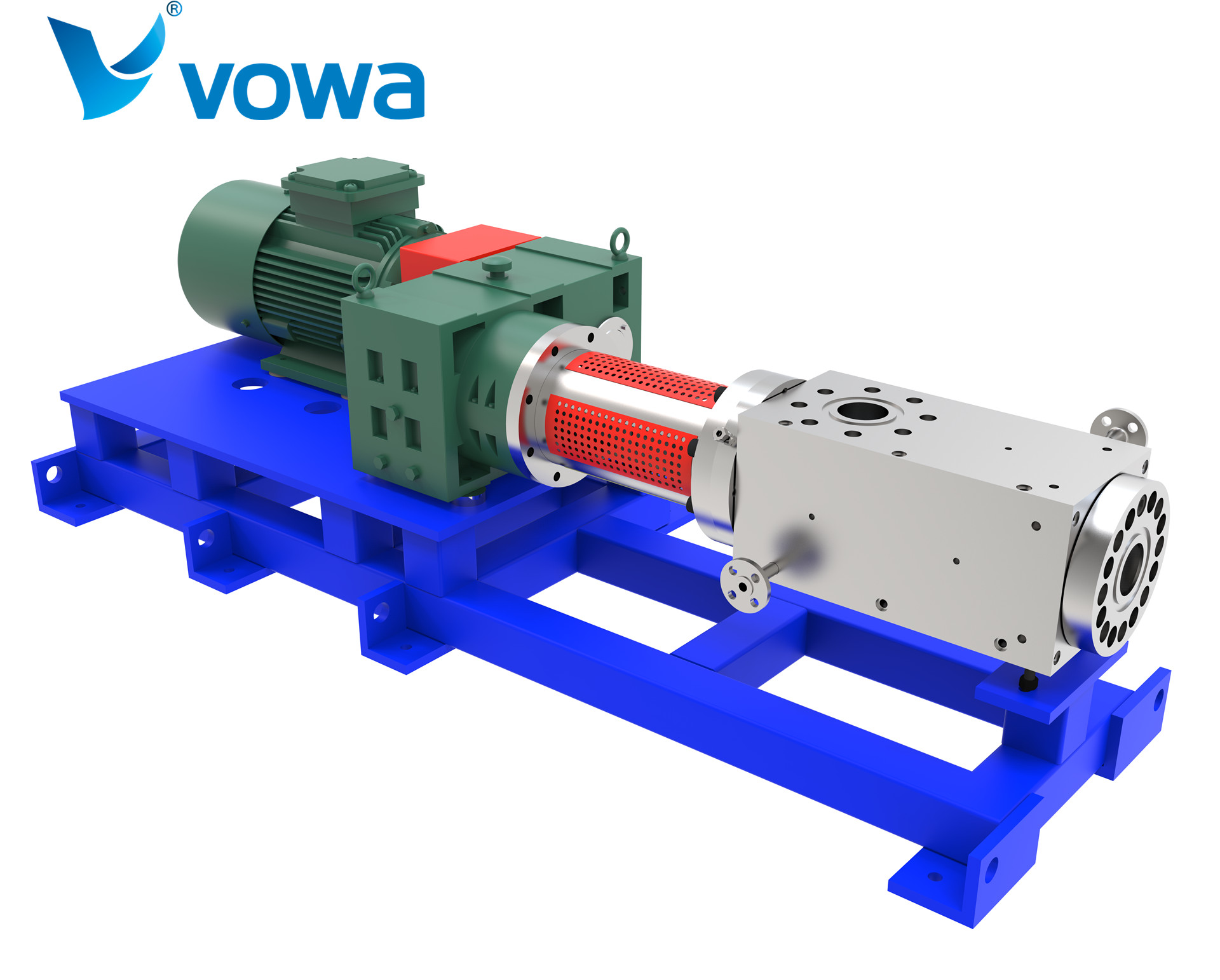

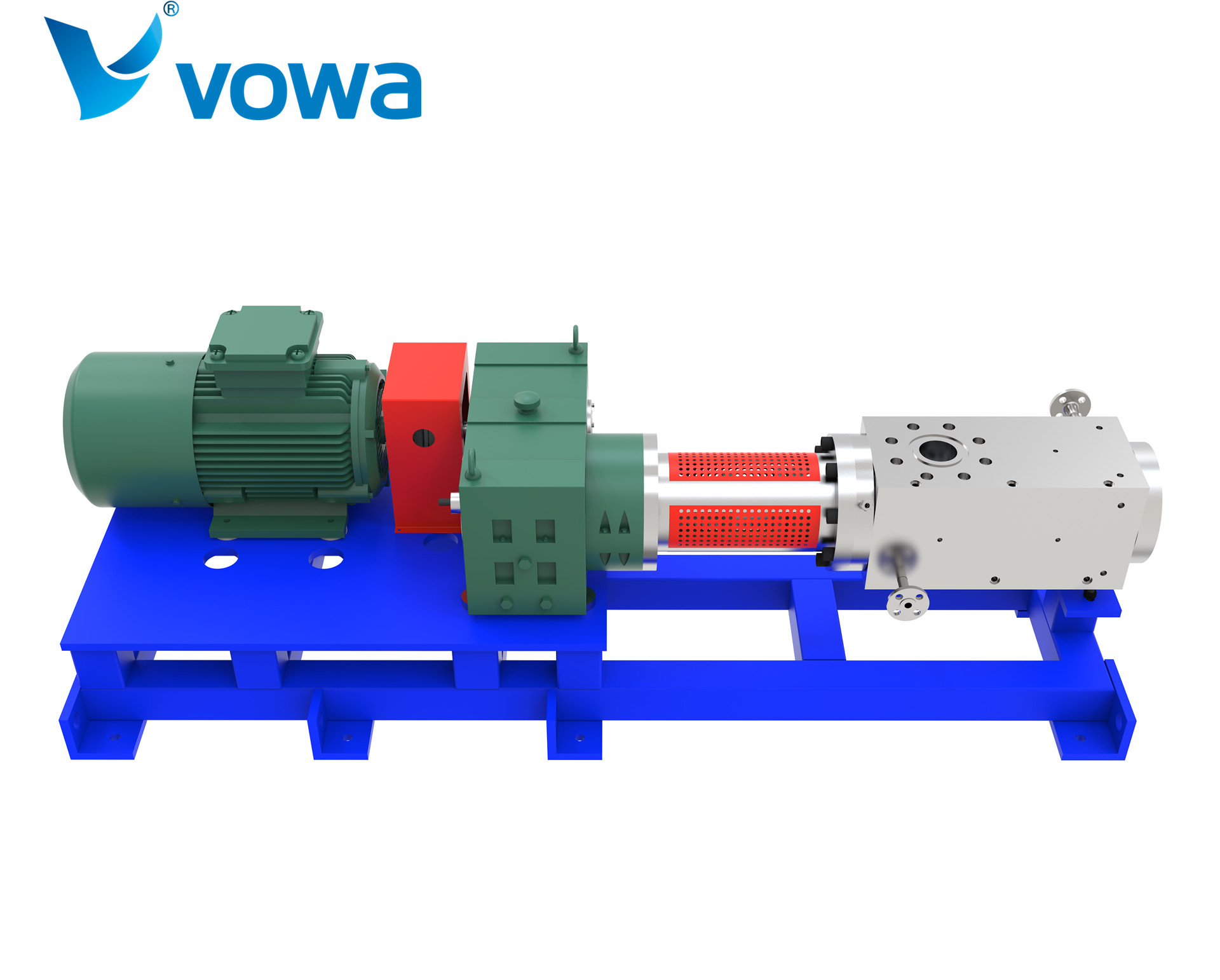

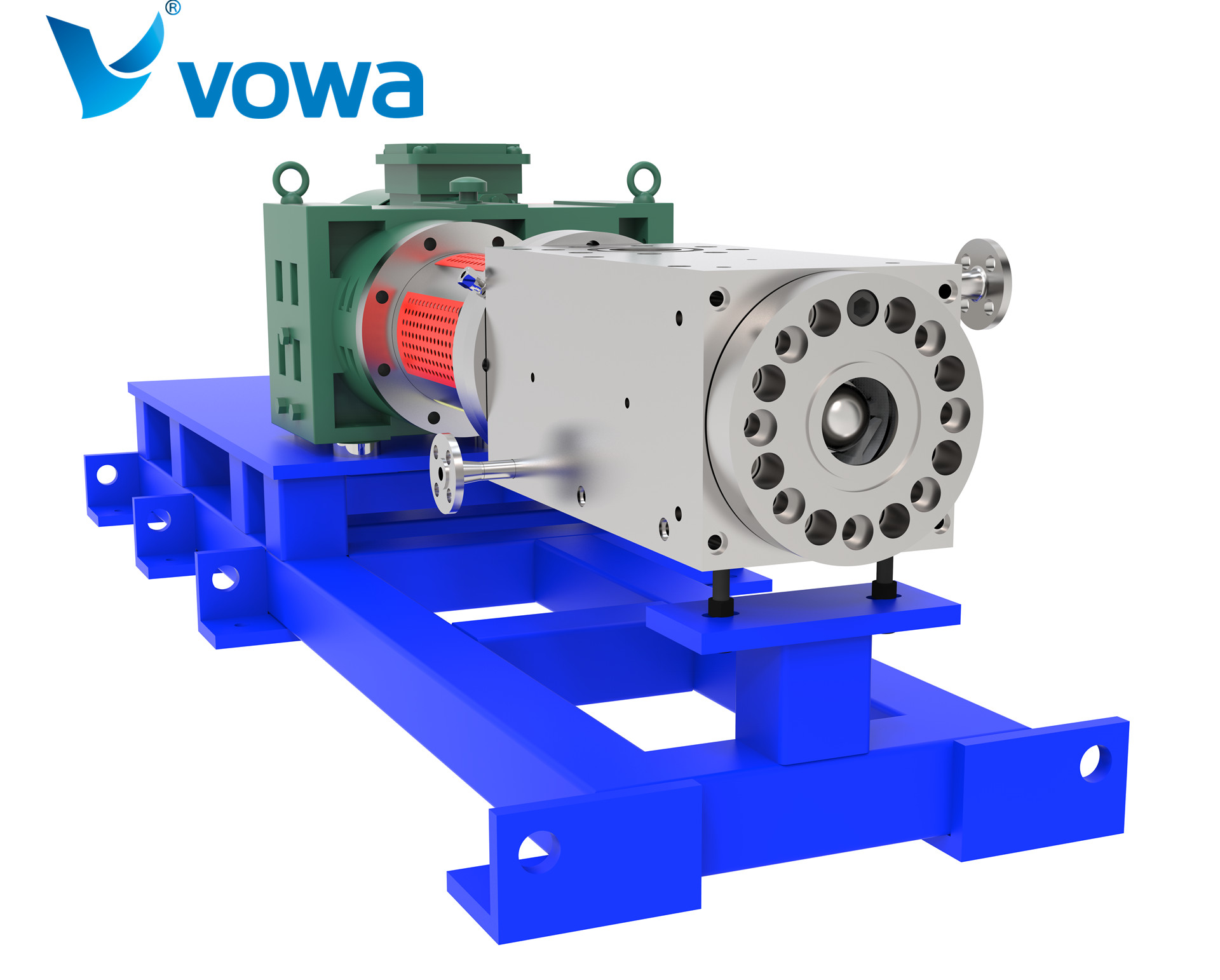

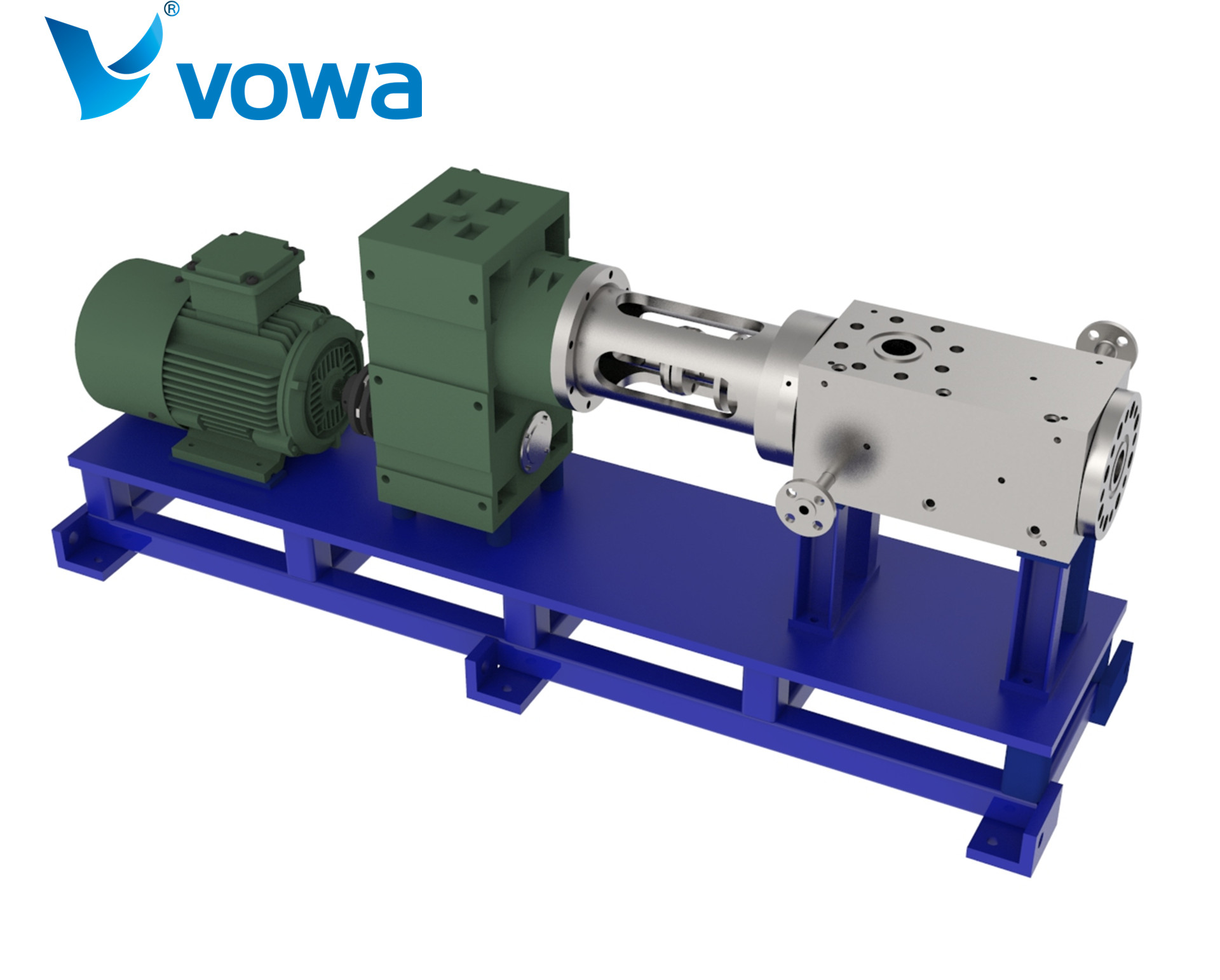

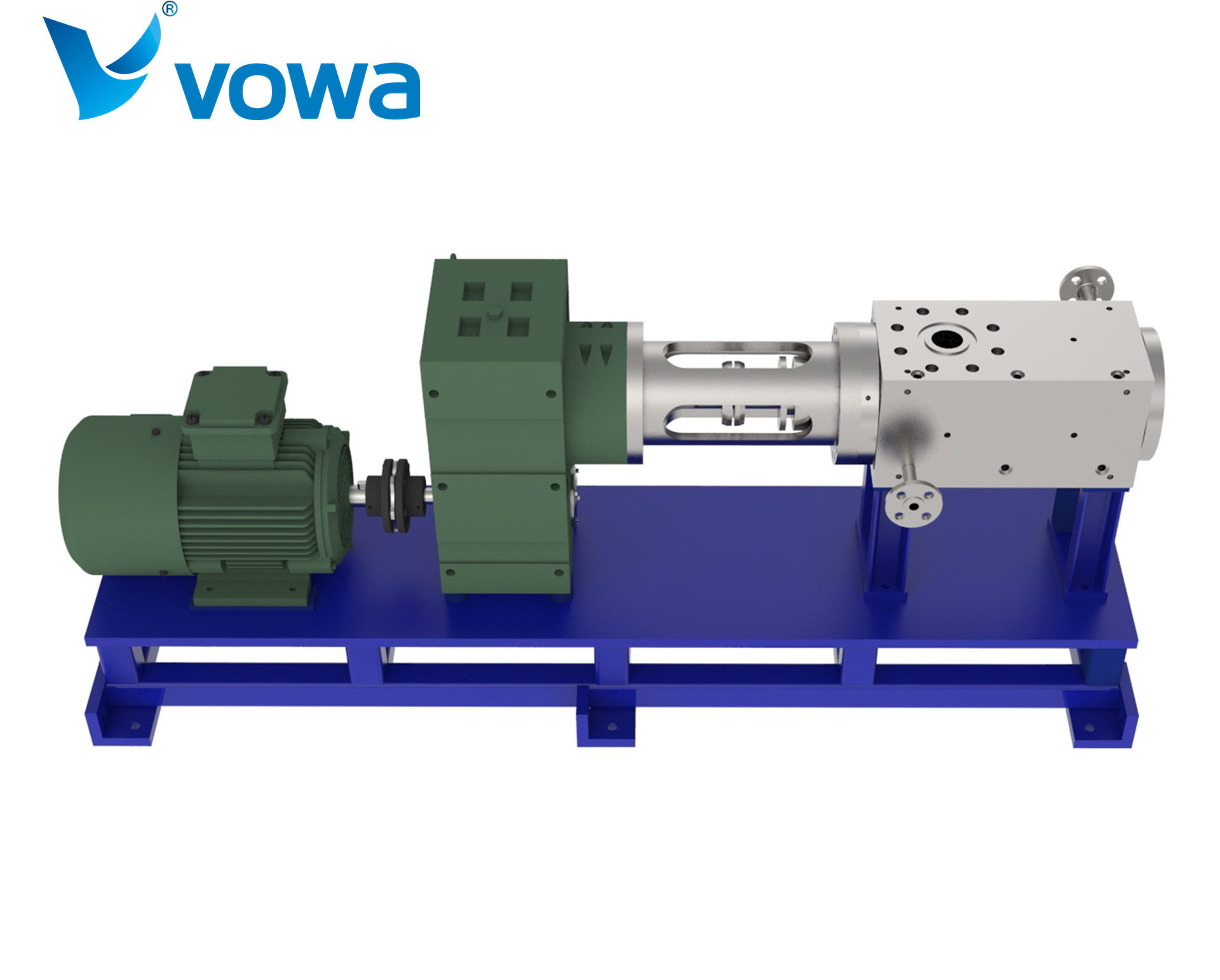

VDM Series Dynamic mixer

——Specially designed dynamic mixer suitable for high temperature polymer

——Suitable for online mixing of a variety of liquid materials

Typical application areas:

Chemical fiber industry: dope coloring

Plastic industry: multi-phase blending, additive addition

Chemical industry: multi-componentmixing

Application conditions:

Temperature: low temperature (-50°C) -> high temperature (400°C)

Pressure: 0 ——> 35MPa

Material viscosity: 0.3mPa.s ——> 40000Pa.s

Technical advantages:

-----Very high mixing efficiency

The optimized design of the dynamic mixing unit can achieve the most adequate mixing of materials in a very short process.

-----Very low pressure drop

The specially designed mixing unit rotor and stator tooth shape can promote the flow of materials and have a minimal impact on the pressure of the materials in the pipeline, which has great advantages over static mixers;

-----Extremely compact structure

Compared with the static mixer, the dynamic mixing unit has an extremely compact structure and a short tube path.

-----Easy to clean

The stator and mover of the dynamic mixing unit can be disassembled, and the design without dead ends makes cleaning easy;

-----Easy to maintain

Adopting an external support structure, the mixing unit adopts a non-contact design and no relative friction parts, so the maintenance workload is very small;

-----Easy to use in a variety of working conditions

It provides a variety of models with different pressure levels and diameters, as well as a variety of heating methods, which can be easily applied in various fluid industries that require mixing.

Materials that can be applied to the dynamic mixer:

Polymer melt

PET PA PE

PP PS HIPS ABS

PC PMMA POM

PLA PBS

Raw liquids, solutions, glues, oligomers, prepolymers, hot melt adhesives, asphalt, paints, adhesives, pharmaceuticals, foods, greases, fuels, oils, dyes, coatings, lubricants in other polymer materials industry, etc.;

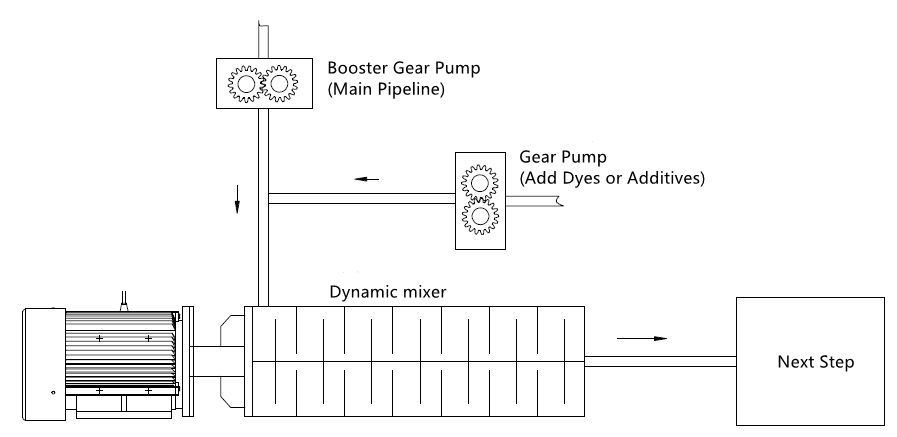

Application diagram of VDM series dynamic mixer

Our company provides integrated solutions such as melt pumps, feeding metering pumps, dynamic mixers, and control systems.

VDM series online dynamic mixer

Specifications and technical parameters

|

Pressure Level |

PN |

5MPa(class300)、15MPa(class900)、42MPa(class2500) |

|||||

|

Mixed series |

n |

8、12、16 |

|||||

|

heating method |

H |

1. Heat medium heating; 2. Electric heating; 3. No heating |

|||||

|

The way to |

DN |

80 |

100 |

150 |

200 |

250 |

300 |

|

Production capacity |

t/h |

1 |

2 |

4 |

10 |

20 |

50 |

|

Driving power* |

KW |

5~11 |

11~22 |

15~45 |

22~75 |

30~100 |

37~160 |

|

Rotating speed* |

r/min |

|

|

|

|

|

|

|

*Depends on material characteristics |

|||||||