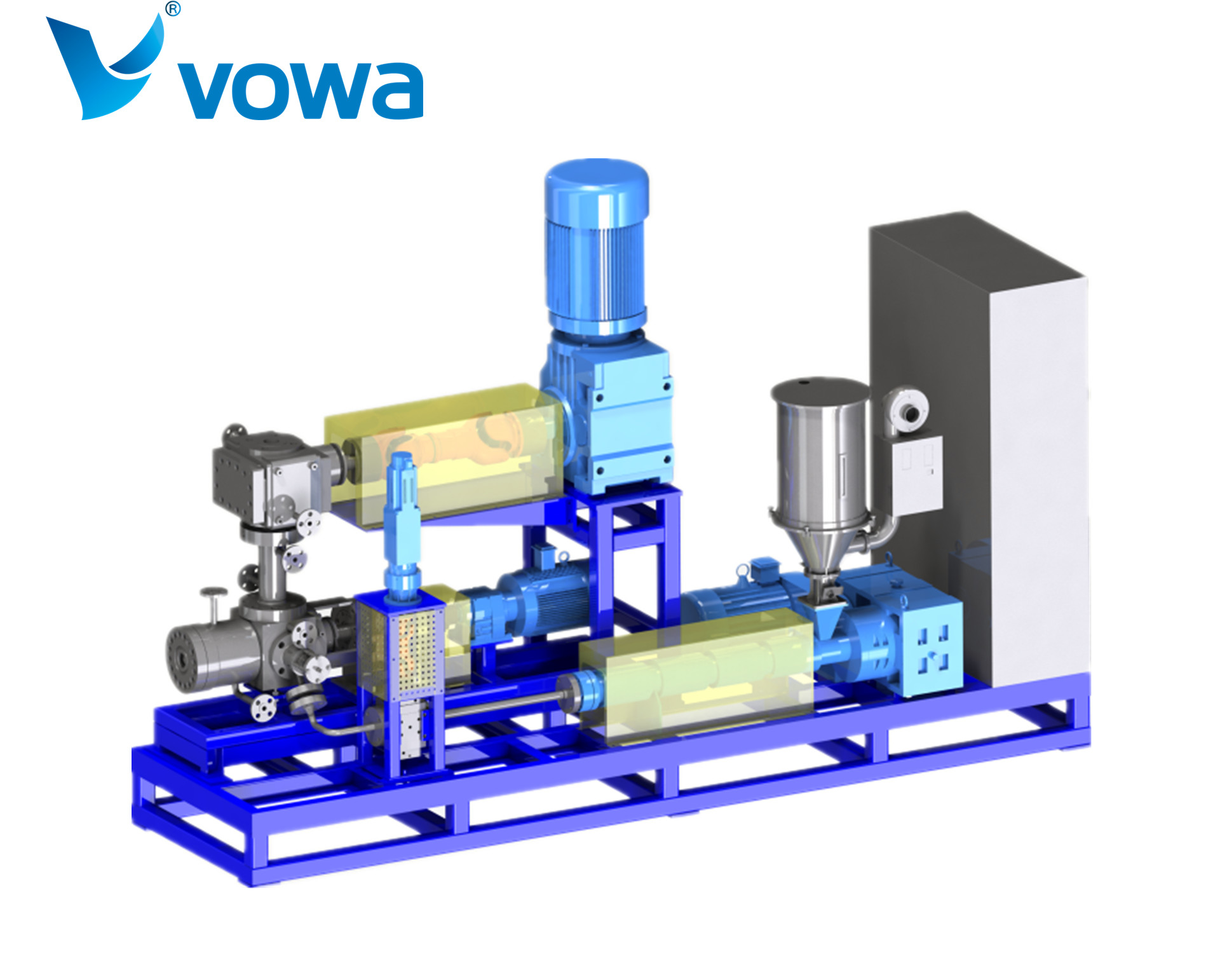

VDM Series Dynamic mixer System

Vowamixer Series On-Line Addition Dynamic Mixing System

Eespecially designed for polymer melt

-----On-Line Addition

-----Dope Dyeing

-----Multiphase Blending

Applicable Conditions :

Temperature :Low temperature(-50°C) ---> High temperature(400°C)

Pressure: 0 ---> 35MPa

Material viscosity: 0.3mPa.s ---> 40000Pa.s

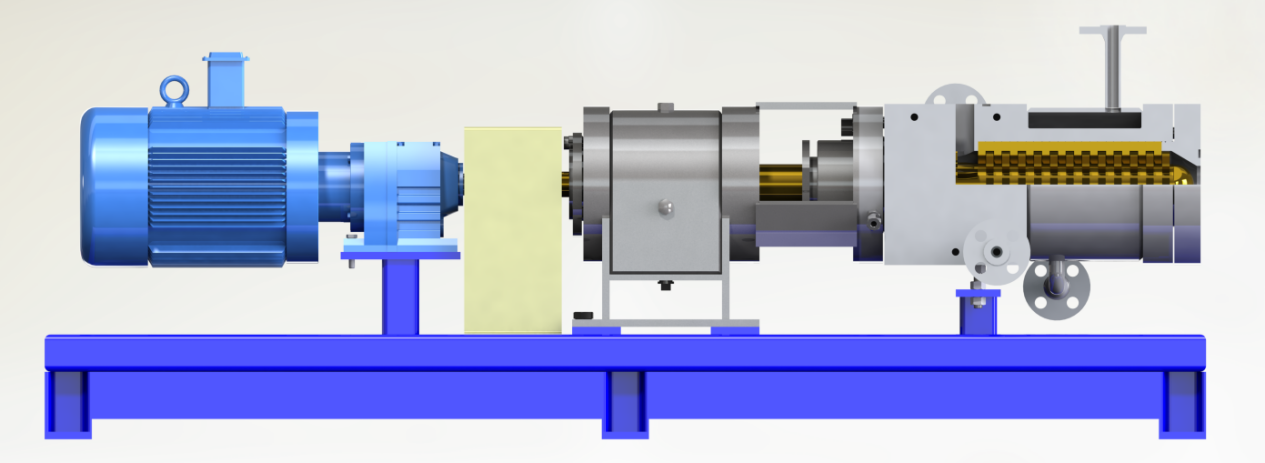

VDM series On-line Dynamic Mixer

Technical characteristics

-----Precise mixing ratio

High precision servo control system is used to precisely control the flow rate of main pipe and the proportion of injection volume of metering pump, thus eliminating the chromatic aberration.

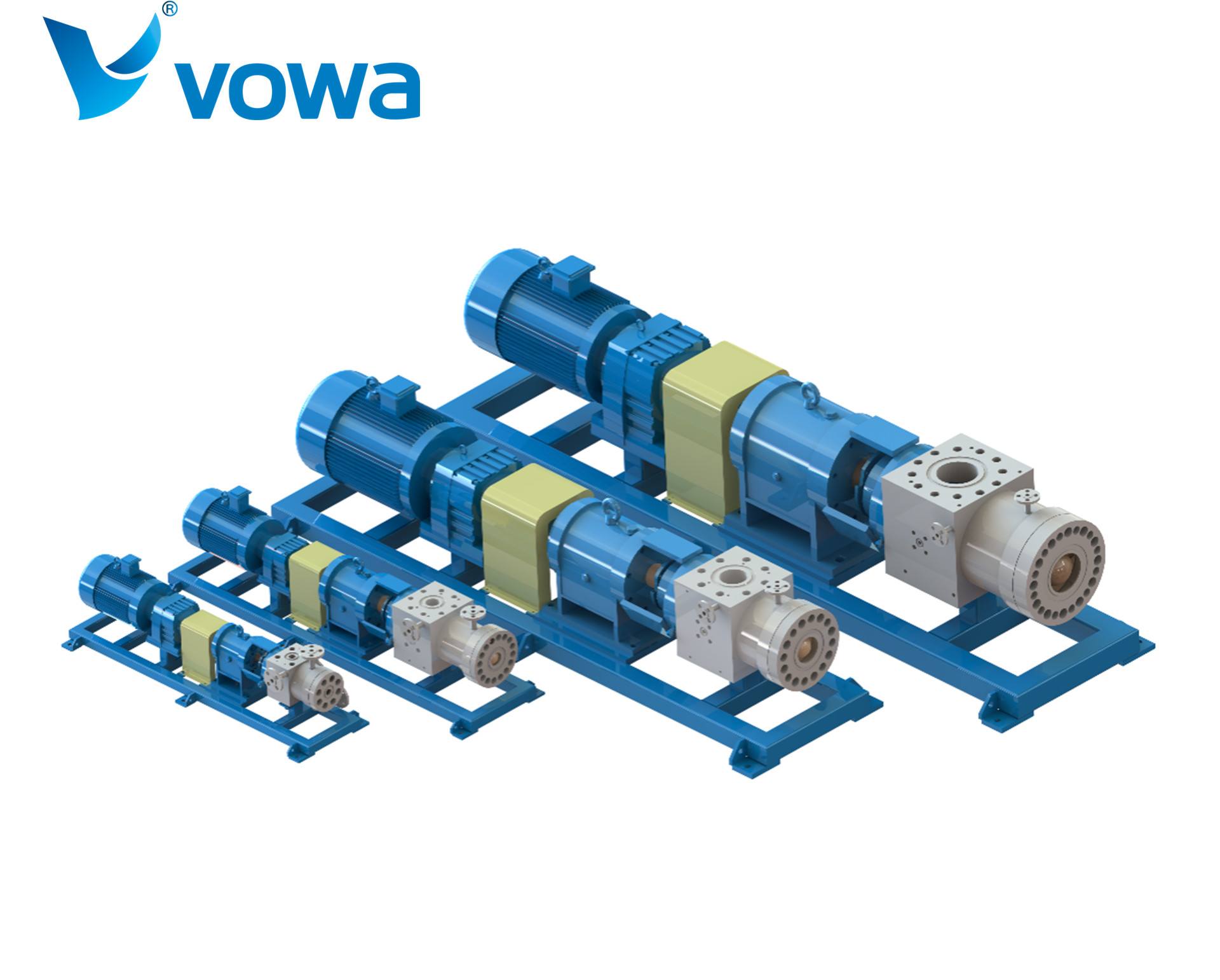

-----Integrated design, small space, easy to install

Adopt the integrated design scheme to facilitate the transformation of existing production devices.

-----High mixing efficiency

Optimized-design dynamic mixing unit which can make material fully mixied in very short process.

-----Low differential pressure

Specially designed rotor and stator mixing unit which can improve the flow of material, so there is an extremely small impact on the material pressure in the pipeline,compared with static mixer,it has great advantages.

-----Extremely compact structure

Compared with static mixer, the dynamic mixing unit has extremely compact structure and shorter tube.

-----Easy cleaning

The rotor&stator of dynamic mixing unit can be both disassembled ,it is easily to clean with no dead end edsign

-----Easy maintenance

By external support structure, mixing unit uses non-touch design, no relative friction parts, so there is little maintenance;

-----Be applicable for various work conditions

Offering the scheme including a variety of different pressure levels, path models, various heating methods, it is easy to be applied in varieties of fluids industry.

VowaMixerⓇ Series On-Line Addition Dynamic Mixing System Schematic Diagram

We provide Melt Pump, Feed Metering Pump, Dynamic Mixer, Control Systems and other integrated solutions.